Sustainability

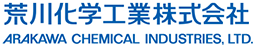

Initiatives towards circular economy

As the movement towards a carbon recycling society accelerates, we aim to maximize the value of natural resources such as rosin and products, and provides products that contribute to the formation of a recycling system in accordance with each individual situation. We believe that activities through the value chain will lead to increasing sustainable corporate value and ultimately improving the ability to regenerate the global environment, and we are working on our business activities from the following perspectives.

✓ Maximization of resource/product value (environmental conservation, product lifespan, recyclability, waste reduction, etc.)

✓ Reducing resource dependence on specific countries

✓ Global expansion of Japanese business models (technology/systems)

✓ Minimization of resource consumption/efficient use

✓Suppression of waste generation

✓ Value chain collaboration

Environmental contribution of products

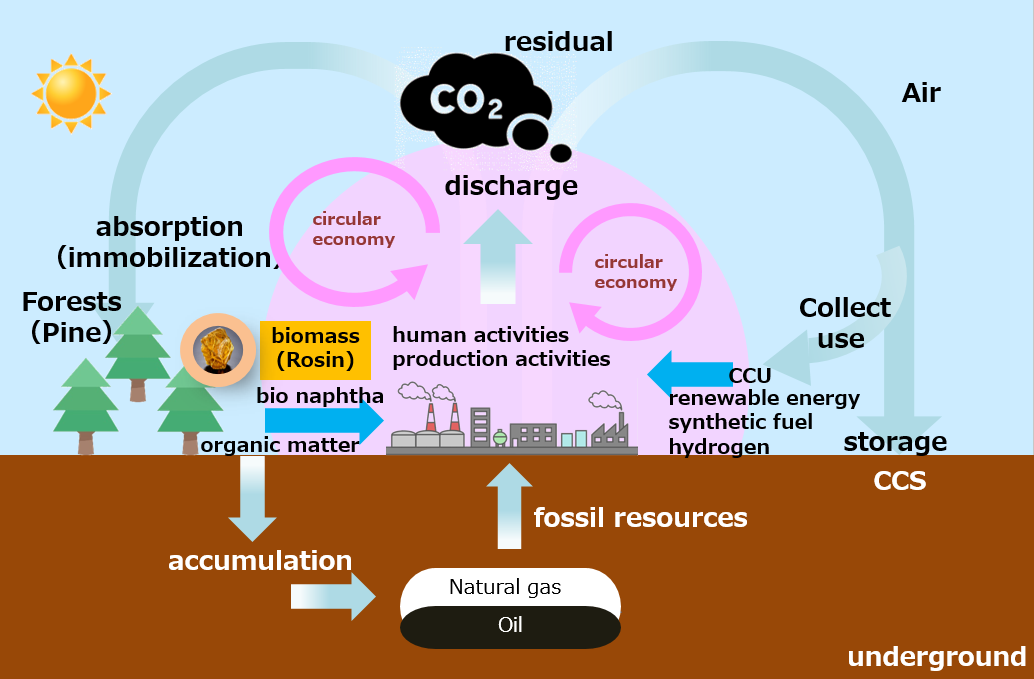

Circular economy contributing to rosin products

CO₂ absorption per ton of pine resin

(Superior natural materials that contribute to carbon negativity)

Rosin, a natural resource, is an important raw material that supports the circular economy in our group's business activities.

Pine trees absorb and fix a large amount of CO₂ during their growth, and we are contributing to the realization of a carbon-circulating society by extracting pine resin from pine trees and producing and supplying it as a rosin product. We are contributing to the realization of a carbon-circulating society by extracting pine needles from pine trees and producing and supplying them as rosin products.As pine trees absorb and fix a lot of CO₂ during the growth process, we are contributing to the realization of a carbon recycling society by collecting pine resin from pine trees and producing and supplying rosin products.Based on component analysis data for pine resin, the amount of CO₂ absorbed per ton of pine resin is equivalent to approximately 3 tons.

*¹ We roughly estimated the theoretical amount of carbon in pine resin, and calculated the amount of CO₂ absorbed by pine resin based on the idea that the carbon source is atmospheric CO₂ absorbed by pine trees.

*² The amount absorbed as a rosin raw material is equivalent to approximately 2.7 tons, based on the assumption that rosin is processed from pine resin harvested in China and transported to our factory in Japan.

First time in Asia*³ Uses renewable alcohol raw materials

For the first time in Asia, we have begun replacing alcohol, which is an auxiliary raw material in rosin products, with alcohol derived from renewable raw materials starting from July 2022. We use renewable raw materials based on the mass balance method*⁴ and strive to maximize product value through value chain collaboration.

*³ As of July 2022 (from raw material manufacturer information)

*⁴ mass balance method:How to track the amount of renewable raw material fed into each raw material tank during raw material production and assign a renewable raw material percentage to each product

Plastic additives that enable biomass production PLAFIT

As efforts to reduce plastic use progress, demand for plant-based plastic additives is increasing.Our company proposes PLAFIT, a plastic additive made from rosin.

It is possible to increase the biomass content by exhibiting new functions while maintaining the properties of plastic itself.

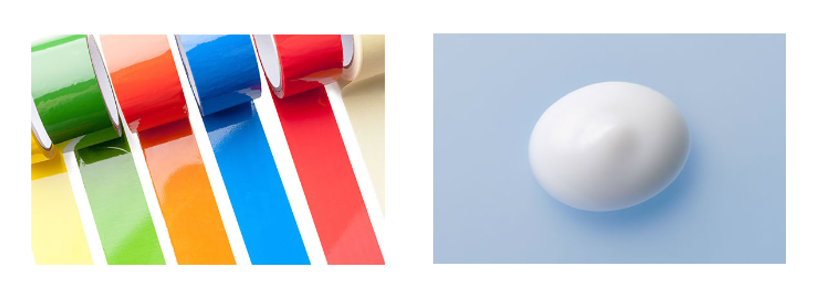

Tackifier essential for adhesion and bonding

Tackifier (tackifier = adhesive agent), which is manufactured from rosin (pine resin) by Arakawa Chemical, is widely used in many adhesive and bonding agents. Tack means "stickiness" and is an essential material for the production of adhesives and tackifiers. Until the 1970s, tackifier was provided to the industry as an organic solvent-based tackifier for adhesives and bonding agents. However, in the early 1980s, when the environmental impact of organic solvents began to become an issue, we began developing emulsion-type tackifiers targeting water-based adhesives and bonding agents, and as a result, we were the first in the industry to successfully develop a high-performance emulsion-type tackifier that contains virtually no organic solvents. As a result, we succeeded in developing a high-performance emulsion-type tackifier that contains almost no organic solvents. After 2000, when environmental regulations were further strengthened, we expanded the application of our tackifiers to the fields where high adhesive performance and quality are required, such as automobiles and housing. At the time, sick house syndrome caused by formaldehyde and other VOC (Volatile Organic Compounds) was becoming a major problem in the housing sector, and all industries had begun efforts to reduce VOC under the national VOC guidelines. Under these circumstances, we developed our own special emulsification technology and achieved complete solvent-free emulsion-type tackifiers in 2003.

Paper strength enhancer that promotes waste paper recycling

ARAKAWA CHEMICAL VIETNAM CO., LTD.

ARAKAWA CHEMICAL VIETNAM CO., LTD.In some parts of the world, such as Southeast Asia, starch is used as a paper strength enhancer, but this creates a large wastewater load and requires time and cost to dry the paper again after it is coated. On the other hand, polyacrylamide-based (PAM-based) paper strength agents can achieve a high yield effect even when added in small amounts, so they can reduce wastewater load. Arakawa Chemical Vietnam Co., Ltd., which started operations in March 2023, is a production base for this PAM-based paper strength agent, contributing to a stable supply mainly in ASEAN, where economic development is remarkable.

Highly concentrated dry paper strength enhancer

;contains functional biomass materials

Growing concern for resource conservation and the environment has focused attention on reducing CO₂ throughout the lifecycle. Specific methods include, for example, increasing product concentration to reduce the number of transports and reduce the amount of transportation fuel-derived materials, and using biomass-derived raw materials to reduce the amount of petroleum-derived raw materials used. As a result of our study, we have developed PS-4000, which has a higher product concentration by blending a specific functional biomass material, while maintaining performance compared to conventional products.

It enables to reduce

●CO₂ generated from raw materials, manufacturing, and wastewater treatment

●frequency of transportation, resulting in reduction of CO₂ from transportation fuel

Drying Powder Technology Brings New Possibilities for Polyacrylamide (PAM)

We have developed technology to process PAM into a powdered form while maintaining its molecular structure, establishing a system to supply powdered PAM. Powdered PAM is easy to handle and readily disperses into other raw materials. This leads to simplification of equipment and increased efficiency in operations. Additionally, since powdered products are more stable than liquid products, long-term storage of the products is possible. Transportation costs can be reduced.

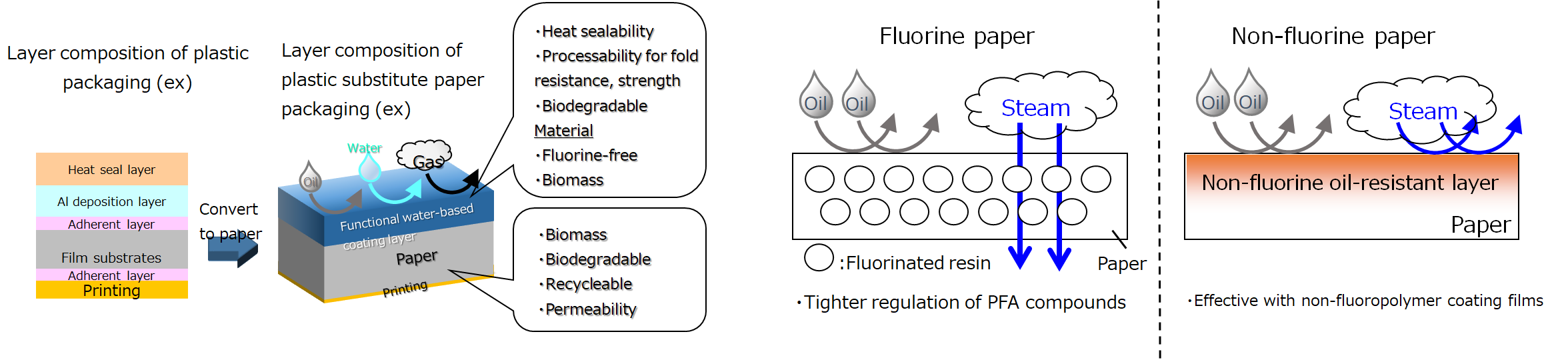

Functional water-based coating agent for paper packaging

As efforts to reduce the use of plastics in packaging materials continue, paper, which is originally a biomass material and biodegradable, is attracting increasing attention. At the same time, there is a demand for paper packaging materials that possess the superior functions of plastics, such as water vapor barrier, oil resistance, water resistance, and heat seal (HS) properties. We are developing the AW Series of safe and secure functional water-based products specifically designed to meet these needs.

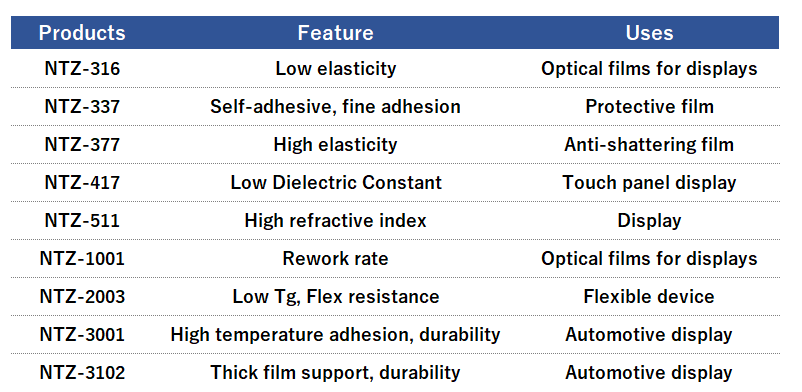

Solventless UV-curable adhesive

One of the applications of adhesives is transparent adhesive for optical displays (OCA), which is used for laminating between touch panels and sensors, bridging the gap between cover panels and modules, etc. In addition to smartphones, which have been the main application for OCA, its use is expanding with the spread of digital signage and vehicle displays. In addition to smartphones, which have been the main application for OCA, the use of OCA has been increasing with the spread of digital signage and vehicle displays. In order to meet the growing demand for OCA in recent years, we have developed the NTZ Series, a UV-curable resin beam set with new functions. Designed based on the polymer synthesis technology, compounding technology, and inorganic particle dispersion technology that we have cultivated in the development of materials, the NTZ series is intended for a wide range of applications in the OCA market. In addition, it is solvent-free and contains no VOCs, contributing to the reduction of environmental impact.

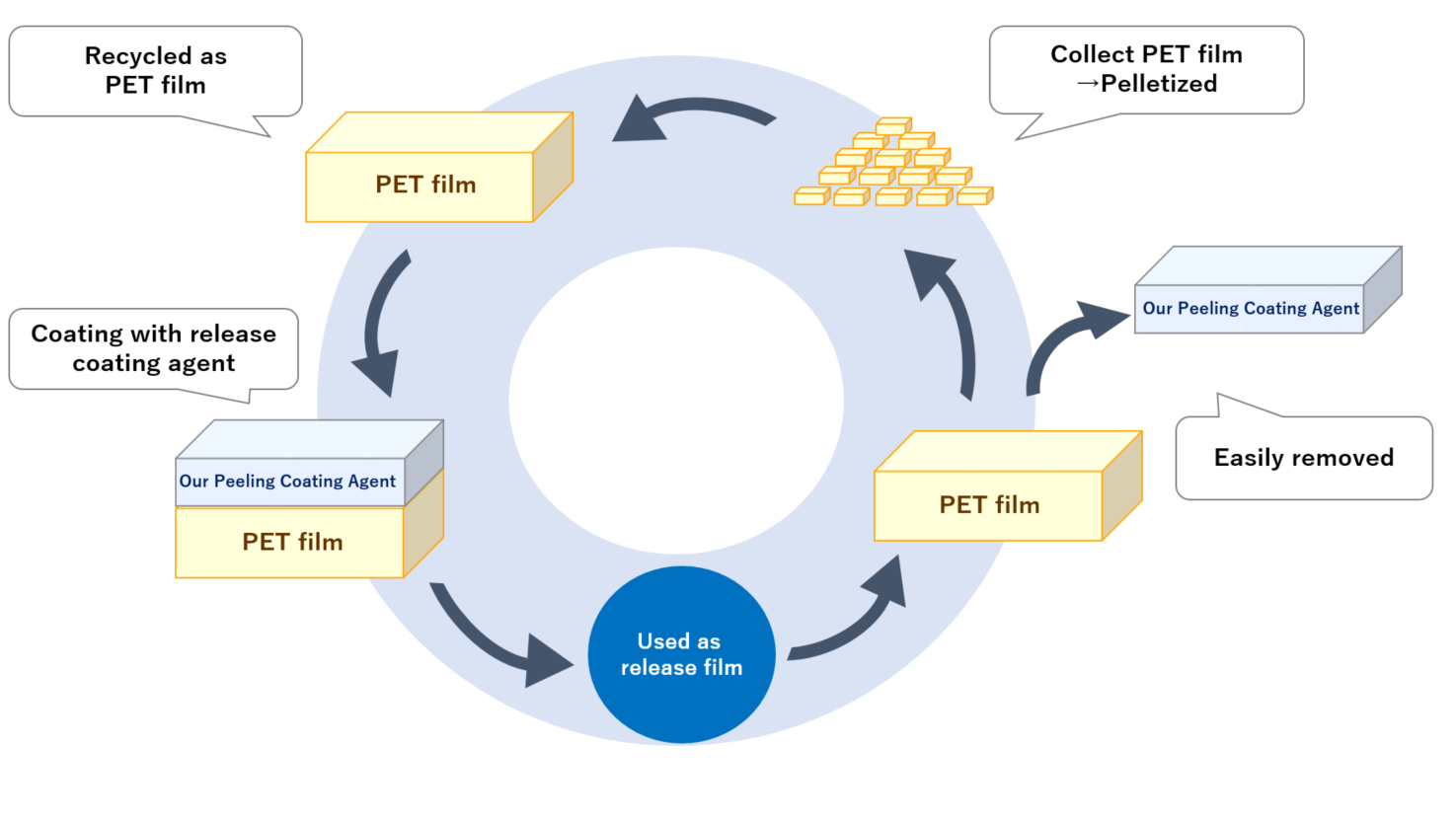

ARACOAT, a release coating agent that contributes to recycling

In recent years, there has been a growing need to recycle plastic film ("PET film") that is disposed of in customers' manufacturing processes. PET film used in the manufacturing process of electronic components is conventionally disposed of as is and incinerated, but there is a need for a release coating agent that can be used as a release film by applying a release coating agent to PET film and then reusing the PET film by peeling off the PET film and release coating agent. There is a need for a release coating agent that allows PET film to be reused by peeling off the PET film and release coating agent.

Against this background, we will contribute to the formation of a recycling society by focusing on the development of release coating agents that contribute to plastic film recycling.